Opening Times:

Monday to Friday 8:00am – 5:30pm

Saturdays 8:30am – 3:00pm

Sundays – Closed, day off with the family.

TILE COLLECTION

We have a wide range of tiles for commercial and household applications; a collection of decorative and durable tiles from top tile manufacturers. Explore our purpose fit tiles:

Explore our range of Bathroom tiles

Explore our range of Kitchen tiles

Explore our range of Non-slip floor tiles

Explore our range of Living Room tiles

Explore our range of Hallway tiles

Explore our range of Outdoor tiles

Explore our range of Patterned tiles

Explore our range of Wood effect tiles

Explore our range of Floor tiles

VISIT OUR SHOWROOM:

Come and visit our showroom to gain a personal sense of the quality, size and style of our tile collections.

SCHEDULE A CALL BACK:

Request a callback, and one of our helpful team members will get right back in touch with you.

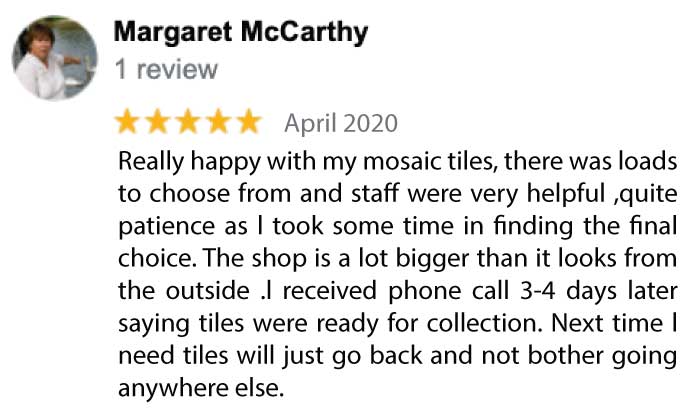

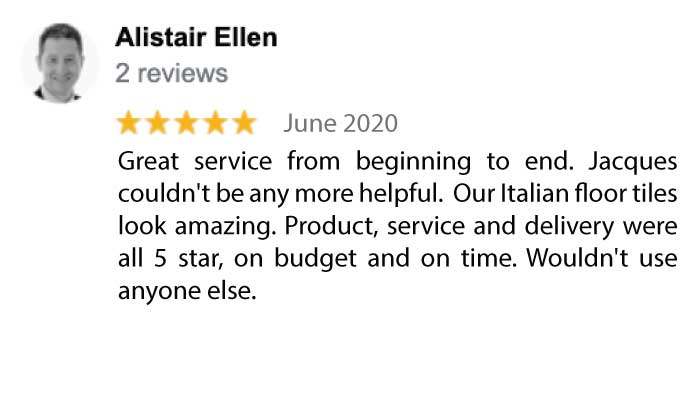

WHAT OUR CUSTOMERS SAY

Make an appointment, or just call in!

On The Tiles,

Mary Catherine House

(Between Go Outdoors and HSS Hire)

Third Avenue,

Southampton SO15 0JU

Opening hours:

Monday to Friday

8:00am – 5:30pm

Saturday

8:30am – 3:00pm

Sunday

Closed, day off with the family.